At the festive opening of the new and renovated Aerospace Structures and Materials Lab at TU Delft Faculty of Aerospace Engineering 27th January 2017, I presented my viewpoint that educating the next generation of aerospace engineers should address more skills that are gaining prominence in future engineering practice, and that the renovated and new labs provide excellent opportunities for their learning and teaching.

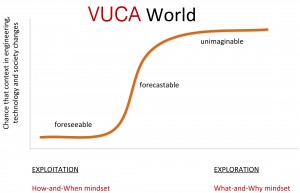

The uncertain VUCA world

“Let me draw a graph that describes our rapidly changing world, the VUCA world that is characterised by high Volatility, Uncertainty, Complexity, Ambiguity. “The first couple of years in the future are, I would say, foreseeable. Although the recent Brexit and Donald Trump’s victory show how unforeseeable even the immediate future can be. What happens after say five years is still forecastable, based on the visible trends today. But uncertainty rises sharply with time. With the current accelerating change in society, engineering and technology, it is unimaginable how the world will look like in about more than seven years from now. Please remember, January 9 this year, it was exactly 10 years ago that Steve Jobs introduced the wide-screen iPod with touch controls, a revolutionary mobile phone, and a breakthrough internet device, not in three products but in one: the iPhone. Can you imagine a world, your life, without a smartphone nowadays? In less than 10 years we all have become a prisoner of the smartphone.”

“Let me draw a graph that describes our rapidly changing world, the VUCA world that is characterised by high Volatility, Uncertainty, Complexity, Ambiguity. “The first couple of years in the future are, I would say, foreseeable. Although the recent Brexit and Donald Trump’s victory show how unforeseeable even the immediate future can be. What happens after say five years is still forecastable, based on the visible trends today. But uncertainty rises sharply with time. With the current accelerating change in society, engineering and technology, it is unimaginable how the world will look like in about more than seven years from now. Please remember, January 9 this year, it was exactly 10 years ago that Steve Jobs introduced the wide-screen iPod with touch controls, a revolutionary mobile phone, and a breakthrough internet device, not in three products but in one: the iPhone. Can you imagine a world, your life, without a smartphone nowadays? In less than 10 years we all have become a prisoner of the smartphone.”

“Acceleration of change: In less than 10 years we all have become a prisoner of the smartphone.”

“Our current engineering education focuses on the foreseeable future, on a mindset of exploiting disciplinary knowledge, making analysis and optimisations and solving problems. It emphasizes the how and when of problem solving in engineering and technology. To better prepare students for less than ten years from now, we would need to teach them more a mentality of exploration, more about the why and what. Which is a very different way of working of problem definition, holistic thinking, creativity, innovativeness, interdisciplinarity and agility. And which requires a different way of teaching.”

How would you characterise the present aerospace engineering education?

“We are strong in educating research scientists. We can be happy with the education we have, but have to think how future proof it is. In the past 30-40 years our engineering education has become increasingly engineering science driven. That is a worldwide trend. Ideally speaking, the analytical approaches of engineering science and engineering practice should be balanced and stimulate each other in our education. The trend however is that the engineering science component has become much more important than engineering practice and design. This trend is not at all aligned with the jobs our students get after graduation. Eighty-five to ninety percent of our graduates end up working in industry. A small percentage of this starts their own venture. Only ten to fifteen percent pursues a scientific career.”

“If you look at our staff, there are far fewer members with experience in engineering practice than 30-40 years ago. Publishing scientific papers is in higher esteem than teaching how to engineer. However, at the heart of every engineer is a maker-instinct: making something that can be developed into a product, a process, a system that works, to add value to society. Professional engineers therefore not only have to embrace the analytical modes of engineering science, but also need to know how to work hands-on in multi- and interdisciplinary teams.”

What are the thoughts of the industry about engineering education having become more academic?

“In the late 90’s the companies Boeing and General Electric, together with Massachusetts Institute of Technology (MIT) and a couple of Swedish universities observed this trend already. They worried about it and developed a framework for a re-engineering of engineering education, the so-called CDIO Initiative. Since 2011 also TU Delft is a member. When I talk with representatives from multinationals like Airbus Group, Total, Vanderlande or RoyalHaskoningDHV, Bosch, Small and Medium-sized Enterprises (SME),young start-ups, or industrial networks like the Netherlands Maritime Technology Innovation Committee, which I regularly do, I hear these worries many times.”

“Nowadays many innovations take place on the fringes of disciplines, or fuse by transferring breakthroughs from one field to another. That requires interdisciplinary thinking, innovation capability and creativity. Take the examples of the enlargement or optimisation of the operations of an airport, or the construction of a wind farm. Engineers working on such highly complex projects must be able to debate with representatives from government and convince financiers and environmental organisations. But learning about such societal, environmental and entrepreneurial contexts, and acquiring and practicing the required social competences, is not strong enough in our engineering programme and do not meet the needs of the future engineering profession.”

What will be the important engineering skills of the future?

“Automation, mass-robotisation, the use of artificial intelligence, 3D-printing and mass personalization of products are strong trends in industry. Around 2030 artificial intelligence might have developed into avatars as a personal assistant, sitting on the shoulder of an engineer and asking questions like: ‘Did you consider this or that solution?’ ‘Shall I consult an expert or look this up in the literature for you?’ What impact would such robotic assistants have on the critical thinking, the lifelong learning and the ethics of our engineers in their profession?”

“There can be no doubt that such developments will have a major impact on our education. If you think about what still distinguishes humans from intelligent machines, you get to creativity, interdisciplinary thinking, collaborating, taking into account ethical considerations and thinking about the bigger picture of a problem −so called systems and holistic thinking. These will be among the key skills for the future.”

“We have to integrate these skills into the classes and projects that we produce. Which does not mean that fundamental engineering sciences or expert knowledge in technology is not important anymore, but other skills are gaining prominence. And thus we may have to re-balance our curricula.”

How do you think the faculty should teach students those new skills?

Hands-on learning in physical labs is appealing for their sensing, visual and active learning.

“I am dreaming of a sort of an innovation backbone throughout our curricula. How exactly to implement this, is still an open issue. I already said earlier, engineers have to do shop work to learn how analytical approaches can be combined with engineering practice. Engineering students bring ideas to life and share their passion for making and testing things by building and experimenting in lab spaces. Hands-on learning in physical labs is appealing for their sensing, visual and active learning. On top of that the learning of entrepreneurial behaviour and personal and interpersonal skills is so much steeper when my students mingle with engineering practitioners from industry and young entrepreneurs. It is also known that working in labs and makerspaces create a strong sense of belonging. Engineering is so much more than what engineers do. We often forget that engineering is a very social activity.”

What labs and makerspaces are we talking about?

“Let me give two concrete examples of projects our faculty is already developing that fit perfectly in my ideas about educating entrepreneurial behaviour that will be a survival skill for the engineer of the future. An excellent example is the Innovative Airport-project. Here the idea is that researchers of TU Delft can use part of the Rotterdam/The Hague Airport as a Living Lab. I would like to involve as many students as possible in this project, also from other engineering disciplines than aerospace, and also students in social sciences or humanities. For all of them it will be a great place to learn to collaborate not just with researchers, but also with people from industry, government and various authorities.”

The first plane that will be assembled by Master students in the new Aircraft Manufacturing Lab of TU Delft faculty of Aerospace Engineering. To learn how to work in an aircraft manufacturing setting, how to perform the project and certification administration according to industrial standards, and how to develop a safety culture and quality assurance system of manufacturing aircraft. And of course to learn lots of tacit knowledge about engineering practice and professional skills such as communication, collaboration and leadership.

A second example, and the one most relevant in the context of the renovation of our experimental facilities in the department Aerospace Structures and Material, is the multi-year project to construct with our MSc students a set of real, certifiable, 2-person airplanes. The idea is that teams of students work in a kind of relay: every team spends a couple of months on building the plane and then hands over knowledge and experience to the next team. Within two-and-a-half years or so the airplane will be ready. The first plane will be constructed from a kit of commercially available components. This project is ideal for students (and our supervising staff) to learn about the complexity of building an aircraft. It will teach them the skills of manufacturing engineering and all those key skills that are becoming increasingly important in the profession of an engineer. In a second phase of the project, parts of the plane will be modified and developed in house and integrated with the plane to experiment on full scale. That is also the phase in which industry may come in and cooperate with our researchers and students. Our new laboratory facilities are crucial for making the step from constructing a real plane based on a commercial kit, to building a real plane based on our own TU Delft innovations.“

Epilogue

In my vision universities will transform from “Centres of Knowledge” to “Centres of Connections” in the very near future. Students come to our campus to meet face to face, to feel connected. Millennial students want to experience the purpose of their work. They want to experience more and more the links with engineering practice. Last week Jet Bussemaker, our Minister of Education, Culture and Sciences announced she will make 10 million euro available for more industrial doctorate studies, to stimulate PhD studies in close collaboration with industrial partners. Also this emphasises purpose and stronger connections between students, universities and industries.

Important capabilities that make our graduates a Delft engineer, are their hands-on mentality, their communication and collaboration skills, and the fact that they have learnt how to engineer. Nobody can learn these skills online. That is only possible on campus by collaborating in project spaces, experimenting and practicing in labs and studios, and developing and building in makerspaces. I don’t believe we will ever be able to educate Delft engineers by online education only, just as I don’t think Facebook, Twitter and Instagram can give me a social life. Online education can never be the be-all and end-all in engineering education. It will also be difficult, if not impossible, to educate Delft engineers in outposts far from our campus. We cannot simply make an outpost in Brussels or New York like Starbucks does. The intensive use of experimental facilities in our educational programmes makes the brand of Delft quite unique.

This post is a more comprehensive version of the interview that has been published on the occasion of the opening ceremony of the Aerospace Structures & Materials lab 27 January 2017. The epilogue is new. The original interview, contained in a colourful brochure together with the interviews of my colleagues about Lighter and more flexible aircraft structures (prof. Chiara Bisagni), Accelerating the innovation cycle (prof. Rinze Benedictus), and Designing novel materials (prof. Sybrand van der Zwaag) is available online.