Mid October 2017 over 200 engineering deans from all over the world convened the Global Engineering Deans Council (GEDC) at Niagara Falls to discuss “issues of importance to engineering education”: the exponential change in engineering and technology, its impact on society and engineering education, and the aspect of diversity and inclusiveness in the STEM field (which I will address in another blog). Because we have “to better prepare our graduates for the fourth industrial revolution, that will continue to transform our world through digital disruption”, as the conference programme announced.

The conference memorised the main goal of engineering education in the second half of the 20th century was to provide engineers for life-time steady jobs in industry. But the 4th Industrial Revolution, replete with automation and ubiquitous sensing, will undoubtedly produce tremendous disruption in economies and the profession of the engineer.

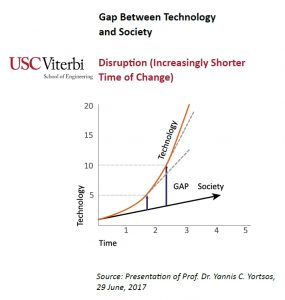

Accelerating growth and development, but not in education

Increasing gap between developments in engineering/technology and society/education (Source: GEDC Industry Forum 2017, p.17)

In many sessions we talked about the exponential change in engineering and technology. Ron Brown of the company EWI Advanced Automation demonstrated the accelerating growth in human knowledge: “In 1900 human knowledge doubled every century, in 1945 every 25 years, in 2013 every 13 months, and soon with the build-out of the Internet of Things, human knowledge will double every 12 hours.

Dave Wilson, Vice President, Product Marketing for Software, Academics, Customer Education of National Instruments, illustrated the exponential change by remembering Moore’s law of increasing the number of transistors on a chip from 10 million in 2000 to 15 billion in 2017. He showed the accelerating growth in FPGA performance (GMACs) that raised by a factor of 4500 in that same period, the power efficiency of ADC converters that increased by a factor of 2500, and last but not least the internet speed that increased by a factor of 800,000 since the mid eighties.

Have we been fast enough?

Many deans of engineering programmes worldwide shared the concern that their programme is stuck in teaching knowledge and skills that made sense when they had to prepare their students for a job in Industry 2.0 (electrically-powered mass production) or 3.0 (automation of manufacturing). The deans took the blame: “We have missed the quality revolution and information technology in the past. And until now we have missed this next revolution, simply because our research universities have moved so far away from our stakeholders, industry and society. We are not not at all ready to adapt our curricula to the impact of this fourth industrial revolution, and the change is incredible”. In many other conferences I also heard the risk as an argument to change: who dares to change pedagogy and take the risk of a temporal dip due to such change? Such barriers mainly apply to programmes that score high in rankings or have obtained a very positive quality stamp by their accreditation agency.

“We have to make our curricula much more agile to be ready to accommodate shift when we need it. And the “when”is now! Many of us see that young academic staff and students are a new breed who are aware, that if you want to change the world, you have to be taught differently. We have to put the hope for change on them”. The deans underlined more than once that the lasting lack of incentives for educational performance and innovation in academic career paths is the threatening barrier and easily kills any will for change. But that at the same time the deans feel incapable to change this dissatisfactory system they have made themselves.

“To change the world, you have to be taught differently”

I also heard positive noise and satisfaction, maybe even some complacency. “We shall not forget the good news we have. In the past 15 -20 years many of us have implemented project-based or problem-based education, online education, flipped classrooms, and developed makerspaces. So we are not static and have made lots of progress already.” But, the echo in the audience was “Has it been fast enough? Are we up to speed for further change? Do we know what to change, and if so, how do it?” These were the pressing questions at the conference and I am not sure they were elaborated enough.

Where will we go from here?

Mind-blowing presentations with futurist forecasts for the next 30 years showed world scenarios filled with smart body implants, zero-size intelligence, internet-connected smart textiles, quantum control, nanotechnology, universal translators, avatars and robotics, virtual holidays to exciting imaginary places and effectively in any body, for instance using it to experience another gender or to be young again, holoportation (virtual meetings via holograms), thought police (thought recognition technology to prevent crimes before they happen), superhuman abilities (exoskeleton cat suits using electro-active polymer muscles), space tourism, supersonic trains. On my flight home they encouraged me to read the fascinating book “The Inevitable” by Kevin Kelly, that outlines the twelve trends in technology that affect how people will work, learn and communicate in future. Kelly concludes his book with the Beginning: we are on the brink of the construction of a planetary system that connects all humans and machines into a global matrix.

The deans did not doubt that the impact on society and the work of the engineer of these developments will be tremendous. A McKinsey impact assessment of Industry 4.0 by industry indicates a 20-50% reduction of time to market, >85% increase in forecasting accuracy, 45-55% increase of productivity in technical professions through automation of knowledge work. “Open your eyes what’s already happening. The rapid change imperils the way we think. The world rushes to embrace the products and services of the four GAFA titanic corporations: We rely on Google for information, we shop with Amazon; socialize on Facebook; turn to Apple for entertainment. These firms sell their efficiency and enable an intoxicating level of daily convenience for the citizen and customer of today, and for the designer and engineer of tomorrow. Do we prepare our students sufficiently to commit to this GAFA life?” (referring to the book: World Without Mind by Franklin Foer). Do we prepare the students in our classrooms sufficiently for the hyperconnected world? Are we ready to educate “comprehenivists”: specialists with deep knowledge in a specific field are needed in the 21st century, but engineers with a higher level and broader understanding of multiple field will be needed as sytems become more complex?

The futurist views were exciting, sometimes overwhelming. But I found them very technically driven. It seems as if engineering becomes, or maybe already is, the centre of society. Should not we expect that future society may also be driven by other concerns and developments than these technological developments alone?

The changing impact of engineering on society, and vice versa

In the opinion of Durban University of Technology the position of engineering in society is changing. Society has to be made the centre of engineering, and no longer should engineering and technology be the centre of society. Engineering and its education will rapidly change from mainly physical towards a technological-social-behavioural-economic discipline. This opinion was underlined by Venkatesh Narayanamurti from Harvard: “Engineering is developing into a central discipline nowadays and a bridge between almost all disciplines. And so engineering is becoming the ultimate liberal art”.

“The university of the future will derive its right to exist primarily from being active in the world and by producing knowledge for the world”(quote prof. Bert van der Zwaan in his recent book Higher Education in 2040 – A Global Approach)

Society and the human person need to get a central role in engineering education, because human behaviour, policies, politics or economics will increasingly override disciplinary expertise when designing solutions for complex problems. I heard an echo of this a month later at the CDIO conference at the Sunshine Coast when Amanda Yeates of the Australian Department of Transport and Main Roads illustrated local as well as international examples, where “the best engineering solutions are not always the best solutions for society or more local communities”. It’s all about societal impact which makes the difference, no matter whether we are talking about civil engineering, energy, biotechnology, robotics, health or aerospace. And it is well proven that it is these connections with society that attract women to STEM disciplines.

Panoramic view of the Niagara Falls from the conference hotel

Changing our engineering education

Two industrial sponsors Quanser and Dassault Systemes mentioned that today’s curricular frameworks are centred around modelling, computing and designing. Today’s engineers don’t solve so many differential equations but design solutions for technical and societal problems, in a business environment that is rapidly changing. “Being competitive is no longer about developing hardware at competitive prices. Increasingly it is about adding a”layer of services” to the hardware, especially software as a service”, Ms. Vittadi, Executive Vice President Head of Engineering at Airbus Defence and Space says in the Industry Forum Report. And so engineer’s creativity, attitude, decision-making, and execution abilities become more important than mere technology.

Wrapping up the sessions on Bio-innovation, Energy, Smart cities and Circular Economy, I believe that engineers who are suitable for the emerging industrial revolution that is enabled by Industry 4.0, will need a QR code of:

- rigour of technical fundamentals of 21st century engineering

- deep skills in data science, data analytics and cybersecurity

- designing products and processes for the environment

- life-cycle systems engineering knowledge

- commercial awareness

- protection of products, IT and industrial frameworks

- empathy for sustainability

- ethical framework: powerful technologies will lead to unforeseen impactful consequences.

In the session on Advanced Manufacturing the panel discussed its concern that the current knowledge and skills level at Master level is insufficient for employment in an environment of advanced manufacturing engineering. Manufacturing technologies become a leading-edge technology but are hardly educated in today’s engineering curricula. Bachelor and Master curricula in any engineering discipline shall be upgraded to accommodate the learning of :

- next-generation robotics

- additive manufacturing

- smart materials

- artificial intelligence and machine learning

- the Internet of Things (IoT)

- predictive analytics

- augmented and virtual reality technologies

Last week the industrial Advisory Council of my Faculty of Aerospace Engineering in Delft also stressed the need to go deep on automation, artificial intelligence, robotisation, computer modeling and (VR and AR) simulation techniques.

The GEDC also discussed the value of adding the a dimension of Mindsets to a curriculum, in addition to the Intended Learning Outcomes of Knowledge and Skills. Examples of such Mindsets could be Growth, an Employer’s perspective, Innovation, Society as the Centre of Engineering, and in my domain the Combat between (the exponential growth in) flying and the environmental impact. Mindsets provide convergence and integration in student learning.

Many of the above statements are in agreement, or had specifically been prepared at the GEDC Industry Forum 2017 in Fontainebleau near Paris in June 2017. The Industry Forum Event Report “Designing the Future of Engineering Education” is available online here.

Who has the courage to change?

It is great that over 200 deans developed some awareness of the urgency to change: “If we are not going to change soon, we are going to loose”. The presentations at the conference were overwhelming and the discussions inspiring. But when I left Niagara Falls I wondered what impact all these futurist forecasts of engineering and technology may have on our engineering education.

It reminded me to the book “Don’t even think about it” by George Marshall. Its subtitle is “Why Our Brains Are Wired to Ignore Climate Change”. It made me realise that thinking about climate change and educational change is strikingly similar: It’s not that universities don’t want to think about educational change. They often decide not to think about it because they doubt the effect of the changing world on their education and therefore chose to place it in the future. It is so abstract, distant, invisible, disputed, and, so uncertain.

“I know many academic staff around me who say “I don’t know anybody who is important to me, who is worried about the impact of the fast changes in technology and society on my education. So it can’t be very important”. (rephrased sentence from the book “Don’t even think about it”)

Students as the change agent

New universities that are built “from the ground up” with completely new curricula, as well as forward-thinking schools of engineering have often the courage to engage students in curriculum development. It is never too early for students to contribute to their own learning and to the development of the engineering programmes. The University of Toronto presented their set-up of first-year undergraduate projects which are either client-proposed or student-defined and developed by teams that have at least 30% foreign students. Just like the European Conference of Engineering Deans in Munich in 2017 (my blog), the GEDC deans have high expectations on the new breed of students as the change agent.

Industry 4.0 is on the threshold

The message I bring back to my university in Delft is the importance and urgency to integrate the new high- demand knowledge and skills in all engineering curricula. They emerge from the revolution that is enabled by Industry 4.0 and cover the spectrum from data science, data analytics, cybersecurity, to next-generation robotics, advanced manufacturing technologies, smart materials, the Internet of Things (IoT), predictive analytics, AR/VR technologies and are applicable to any discipline in design, engineering or sciences! At TU Delft I see an initiative this year to incorporate an introductory course in Python programming in those engineering curricula that have missed the Third Industrial Revolution of Digitalisation over the past 25 years… It goes without saying that an introductory Python course is only a drop in the ocean of what is needed to prepare our students for the digital age.

The message I bring back to my university in Delft is the importance and urgency to integrate the new high- demand knowledge and skills in all engineering curricula. They emerge from the revolution that is enabled by Industry 4.0 and cover the spectrum from data science, data analytics, cybersecurity, to next-generation robotics, advanced manufacturing technologies, smart materials, the Internet of Things (IoT), predictive analytics, AR/VR technologies and are applicable to any discipline in design, engineering or sciences! At TU Delft I see an initiative this year to incorporate an introductory course in Python programming in those engineering curricula that have missed the Third Industrial Revolution of Digitalisation over the past 25 years… It goes without saying that an introductory Python course is only a drop in the ocean of what is needed to prepare our students for the digital age.

On page 29 of my report “Engineering Education in a Rapidly Changing World” I wrote that digital literacy, a catch-all for many aspects I mention above, has to become a basic literacy in higher engineering education. In business an exponentially widening gap between product performance and customer demands would lead to sleepless nights for many CEO’s. Is not it fascinating that academia can live so long in their own bubble, disconnected from the revolution that takes place in the way we engineer and design in engineering business?

The deans at Niagara Falls were thrilled by the stories about rapid developments and futurist forecasts in technology. But I missed the sense of urgency to change. Time will tell who ramped up the investment in particularly the digital literacy skills, to ready their graduates for the next technological age of Industry 4.0.